Component Failure

With the exception of the battery system, there are two other critical functioning components which have a finite life and are integral to UPS performance, they are the Capacitors and Cooling Fans. Failure of either could cause the loss of connected load, the premature ageing or destruction of other components and result in costly downtime. Here we discuss the reasons why, some frequently asked questions and how to best to avoid this drastic outcome.

Cooling Fans

Why do UPS cooling fans fail and need replacement?

Cooling fans are one of the few UPS components that are mechanical in nature, they run continuously while the UPS is online and therefore are subject to mechanical wear.

The electronic components inside a UPS switch at a very high frequency and so create a tremendous amount of heat. For instance a 200kW UPS system running at nominal load and operating at 95% overall efficiency will generate around 10kW of heat, this heat needs is expelled by means of the cooling fans moving a tremendous amount of air through the UPS.

Sealed bearings inside fans contain grease, which dissipates over time due to increased temperature. This results in the fan speed slowing which in turn creates more heat and noise. The build up of dust on the air intakes also increases the temperature and forces the fan to work harder to keep the air moving.

Single Fan Failure

Most UPS manufacturers design their UPS to operate in ambient temperatures up to 40°C at nominal load and sometimes contain redundant fans. As ambient temperatures around the UPS are typically lower and not run at full load, if a single fan fails, the UPS may continue to operate online for a short period of time until the fan is replaced. It is not recommended to continue running for long periods with a defective fan as internal component temperature will rise and subsequent premature ageing will occur.

Multiple Failure

If multiple fans fail and the internal UPS temperatures rise above an operating threshold the UPS will normally transfer to static bypass, although the connected load will continue to be powered by raw mains, it will be susceptible to input power variations and remain unprotected from outages. The fans should be replaced immediately and the UPS restored to an online condition.

Do I know when my fans will fail?

It is possible that before a total failure the fan will start to make audible noise as the grease dissipates and fan bearings start to run dry. Some manufacturers also have tachometers, which will sound an alarm when the fan speed decreases below an acceptable level.

The cooling fans’ service life is affected by the ambient temperature around the UPS, the environment and the load level applied to the output of the UPS.

Preventative Replacement

Most manufacturers recommend a preventative replacement at between five and seven years. Although replacing fans that have not yet failed may seem wasteful, the cost of an individual fan is normally significantly less than the associated labour expense of a UPS engineer along with the time scheduled to take the system offline to complete the replacement. Not only will the preventative replacement of fans be more cost effective than replacing them individually as they fail, it will also minimise the period of time the connected load is at risk while running on mains power while the UPS is in bypass mode. As capacitors typically have the same service lifetime, it can make sense to replace both sets of components together. See capacitors below.

Summary

Cooling fans degrade over time and have a service life of around five to seven years under good environmental conditions, it is rare a single fan may fail before this time, but if so it should be replaced as soon as possible.

Arranging for a preventative replacement of all the cooling fans at a fixed interval is the most cost effective method by saving on labour expenses and arranging maintenance windows. It is also the best way to increase the reliability of performance of the UPS, reducing the chances of losing the connected load and costly downtime.

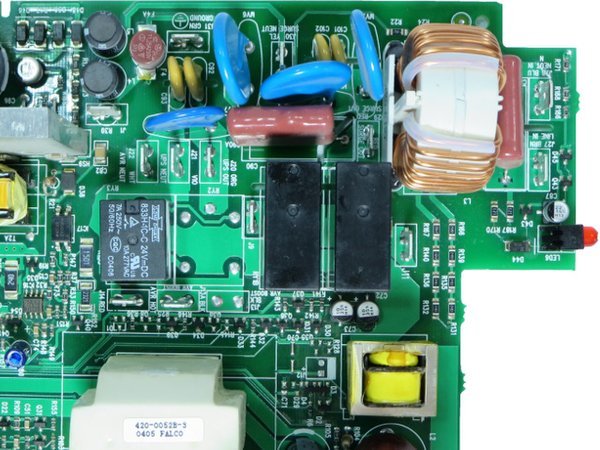

Capacitors

Capacitors are components inside the UPS that smooth out fluctuations in electrical voltage. A three phase UPS may contain hundreds of capacitors, connected in banks for specific roles. They dampen out any changes filling in the troughs and eliminating the peaks to maintain a constant level. They are used for both DC (Direct Current) and AC (Alternating Current) power circuits within the UPS.

How long will my capacitors last?

Capacitors have an operational lifetime calculated by the manufacturer according to the rated voltage, current and ambient temperature. The lifetime can be optimised by avoiding running the UPS at full load or with a high ambient temperature, but the capacitors are consumable and will fail during the service life of the UPS. Depending on the manufacturer, this is usually between five to seven years. Capacitors should be visually inspected and checked during each service visit.

When should I replace my capacitors?

Waiting for ultimate failure of the capacitors will usually cause damage to surrounding components and possibly cause an interruption to the UPS output, especially if the AC output capacitors fail. Replacing the capacitors as a preventative measure when checks show signs of distress or when recommended by the manufacturer will avoid a UPS failure and potentially costly downtime.

Should I only use OEM components?

The capacitors installed by the original equipment manufacturer (OEM) should be of a premium tested brand and will have a specific voltage rating (Voltage), a storage potential (Farad) and physical dimensions. Where OEMs have experienced premature or unexplained failure of capacitors, they normally would switch to another premium brand during manufacturing lifecycles. The replacement components, should as a minimum meet the original specifications. Requesting the specifications of the components will allow a user to find a comparative quotation, but this will need to be requested or recorded during the service visit as normally a manufacture specific part code will usually be quoted.

Summary

Prevention is better than the cure. The AC and DC capacitors are of a limited service life which is normally shorter than the service life of the UPS. Regular checks of the capacitors during servicing and replacement when issue arise or when the service life has been reached avoids larger issues caused by capacitor failure. Capacitor failure has been the cause of fire suppression being triggered, damage to other internal components, loss of load and even fire. The preventative replacement of all the capacitors once signs of raging are apparent helps avoid these major issues. As capacitors work together in banks, if one fails it is often more cost effective in site labour and downtime to complete a full replacement.