Uninterruptible Power Supplies installed in harsh environments

The ideal environment for an Uninterruptible Power Supply (UPS) and it associated battery set, would be in an area that is secure, dust free, dry with an ambient temperature maintained between 20-25C and adequate airflow to meet the manufacturer requirements.

When installing a UPS as part of a new build project or renovation works, the environmental requirements are usually carefully considered and the UPS will be ideally located in order to increase reliability and maximise the operating life.

Sometimes, if the UPS is retrofitted to an existing electrical infrastructure, the ideal environment often isn’t physically available. With poor planning, designers locate the UPS alongside other electrical equipment, such as switchgear located in plant rooms, basements or even outdoor containers. The UPS then may have to contend with the elements of a harsh environment. If this is the case, how can the effects of a poor environment be mitigated?

Separate Battery Location

The operational ambient temperature of the majority of UPS models is specified as 0C to 40C (assuming no condensation), in this window the UPS will perform without a serious effect on its overall life, as long as consumable components such as capacitors are preventatively checked and replaced when required. The batteries however are a completely different story. Although the specification sheets will state a similar operational window, the service life and performance, drastically alter depending on temperature.

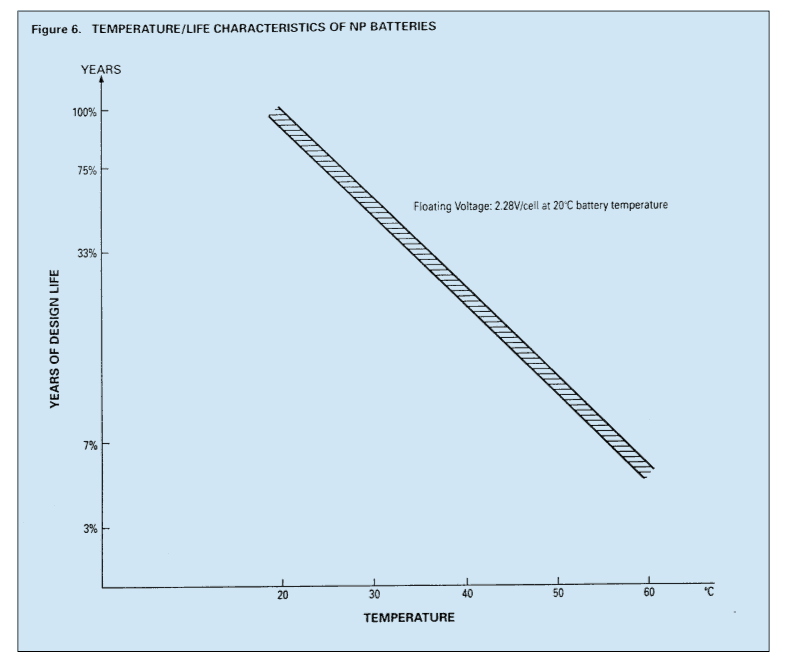

Most battery manufacturer specification sheets state the performance characteristics and service life at 20C. If the temperature is higher, the performance will increase but the lifetime will decrease. If the temperature is lower, the lifetime will increase but performance will decrease. Its a very substantial drop off, the specification of a Yuasa five year design life shows that with an ambient temperature of 30C, the battery would only be useable for 33% of its design life. That’s just over 1.5 years!

One method to remedy this would be to construct a dedicated area just for the battery installation, which is temperature controlled. This also helps with power savings, as batteries give off minimal heat (unlike a UPS). If the temperature cannot be maintained then select longer design life batteries such as ten or twelve year blocks and check their performance regularly. Although initially more costly, it avoids annual battery replacements and a ten year design life battery is not twice the cost of a five year block.

Dust Filters

In normal operation, the UPS is always running and so a constant flow of air enters and exits the system. If the environment is prone to dust or other airborne particles, the inside of the UPS can become clogged, not only causing cooling problems but coating the internal components with debris and potentially causing failures. Selecting a UPS which features dust filters as standard or which have the option for retrofitting and regular replacement will prevent harmful internal build up of dust compromising the reliability of the system. In extremely poor environments “Conformal Coating” may also be recommended, see below.

Conformal Coating

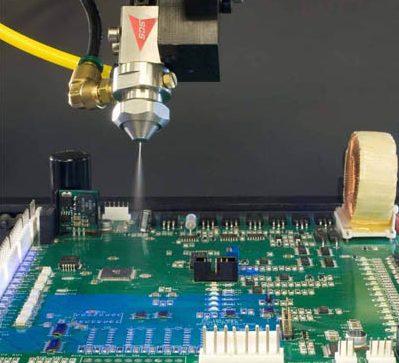

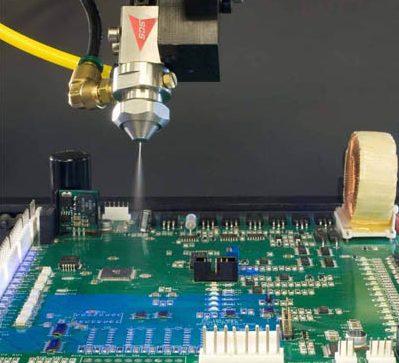

As already mentioned, the ambient air (and associated airborne particles) are blown through a UPS constantly throughout its service life. Where the air may have moisture present, a chemical contaminant or high humidity content, some manufacturers offer the option to apply a “conformal coating” (sometimes called tropicalisation) to the internal circuit boards. The Conformal Coating is a protective chemical coating applied by the manufacturer before shipping. By being electrically insulating, it maintains long-term surface insulation resistance, thus protecting the electronic assemblies from air-borne contaminants such as salt spray, which will assist in preventing corrosion. This procedure was historically used for “industrial” UPS, but now manufacturers such as Huawei and AEC use this technology as standard on their three phase UPS range.

Summary

Cooling fans degrade over time and have a service life of around five to seven years under good environmental conditions, it is rare a single fan may fail before this time, but if so it should be replaced as soon as possible.

Arranging for a preventative replacement of all the cooling fans at a fixed interval is the most cost effective method by saving on labour expenses and arranging maintenance windows. It is also the best way to increase the reliability of performance of the UPS, reducing the chances of losing the connected load and costly downtime.